Irrigation professionals are frequently called upon to rescue failing systems and rectify crippling water bills, serving as vital problem-solvers for both residential and commercial clients grappling with the consequences of inadequate irrigation. Invariably, the root cause of widespread irrigation problems is critical hydraulic failures. These failures create systemic imbalances that lead to insufficient flow, uneven distribution, unnecessary wear and tear on components and, ultimately, significant and costly repairs and inefficiencies.

Irrigation hydraulics center on efficiency, pressure and uniformity — hallmarks of a properly designed, installed and maintained irrigation system, says Don Davis, CIC, CID, irrigation training manager at SiteOne Landscape Supply in Cary, North Carolina. Remove any one of these tenets, and system failure is inevitable.

“I liken this to the three legs on a stool,” he says. “Lose any one of those legs, and the stool falls over.”

Irrigation pros offer insights and their experiences to address common hydraulic-based issues.

Start at the source

Maintaining proper pressure, especially on more significant commercial and residential properties, is key to properly functioning irrigation systems. If the system is fed from a source other than standard municipal water, adequate pressure begins at the irrigation pump. Or, if there are low-pressure issues within the irrigation system — such as covering a large area, excessive sprinkler heads or uneven topography — the solution may involve a booster pump.

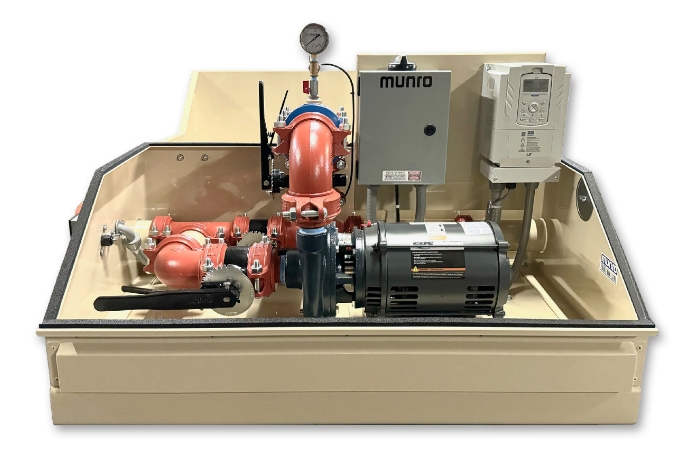

“Pumps can kind of be a black hole for some people,” says Justin McDaniel, product manager for pump stations at Munro, based in Grand Junction, Colorado. “Do I have the right pump? Is it the right size? How do I size the pump correctly? Being diligent about pump selection is a big deal.”

Pump selection starts by determining whether it’s required for suction lift or pressure boosting. McDaniel says the key challenge, especially with booster pumps, is understanding the difference between static and dynamic pressure.

He explains that static pressure is the pressure exerted on a system when no water is flowing through the system. Conversely, dynamic pressure is the water pressure when it’s moving through the system. As the system operates and water flows, the dynamic pressure is typically lower than its static pressure.

According to McDaniel, it’s not unusual for irrigation plans to only provide details on static pressure, which fails to account for the hydraulic losses from backflow preventers, water meters and pipe friction. Suppose a pump is sized based solely on static pressure. In that case, the actual dynamic pressure available to the irrigation system might be significantly lower, leading to insufficient pressure to operate it as designed.

Therefore, precisely determining dynamic pressure is paramount to selecting a pump that will deliver reliable pressure throughout the entire irrigation network. McDaniel says any miscalculation here will inevitably lead to systemic inefficiencies and performance issues.

“Really understanding the available dynamic pressure from a water source is critical in the sizing and selection of the pump to provide the correct pressure for the irrigation system,” he says.

Filter out issues

Troubleshooting irrigation performance and pressure loss involves inspecting and maintaining filters, including self-flushing and automatic types, says Justin McDaniel, product manager for pump stations at Munro.

“Pump stations and irrigation systems have filters in them,” McDaniel says. “Those filters can cause significant pressure losses if they’re plugged up. And never assume that a self-flushing or automatic filter will take care of itself.”

In addition, McDaniel says that adjusting screen filter sizes is essential when dealing with water containing heavy loads of sediment. Water sources with heavy sediment contamination will clog filters, leading to pump shutdowns and system failure. As a result, additional prefiltration or additional filters might be necessary.

“In Arizona, we had some filtration issues on a system,” he says. “It got to the point where the water was so bad that it shut down the pump stations. Everybody was walking throughout the park wondering why everything was dying. In the end, the well providing water to the irrigation system was sending a lot of sand that was plugging the filters up. That can create a tremendous amount of hydraulic issues, for sure.”

Visual check

When troubleshooting hydraulic issues, gaining a visual perspective and attempting to identify leaks and line breaks is essential. Especially when dealing with smaller residential and commercial systems, visual inspections are critical, says Tucson, Arizona-based Rick Malkin, product manager at Rain Bird Corp.

A simple routine site walk-through will reveal obvious issues such as puddles, broken heads or dry spots in the landscape, indicating valve problems. In addition, observing plant health and checking system pressure with a pressure gauge provide irrigation pros with valuable clues to assess the situation, Malkin says.

“From a hydraulics standpoint, you’re looking for something that tells you there’s a leak or break somewhere in the system,” he says. “So, you see a geyser, and that clearly indicates a head broken off somewhere. But let’s say you see plant material dying off or dry spots and brown turf areas. That’s a good indication that you have a bad valve, and the problem is a bit deeper.”

Hydraulically, leaks cause pressure drops, affecting the entire system’s performance and leading to costly inefficiencies, Malkin says. “So, a lot of things here are connected hydraulically,” he adds. “If I have excess flow, it’s going to cause my pressure to drop. If I have too little flow, then my pressure goes up.”

In larger commercial systems, technologies such as flow sensors, monitoring and remote-access central control systems enable real-time flow analysis, allowing irrigation pros to compare pressure and flow to expected levels, Malkin says. This data narrows the search parameters for locating potential leaks or breaks and significantly streamlines the troubleshooting process.

“Most systems will have recorded what the [irrigation system’s] flow should be, and then [the irrigation pro] can monitor in real-time whether it’s too high or too low,” he says. “If the flow is excessive, then most likely there’s a break somewhere out there. It gives you something to start looking at.”

Pressure

While flow and pressure are related hydraulic principles, they should not be confused as the same thing, according to irrigation pros. Flow refers to the volume of water moving through the irrigation system, commonly measured in gallons per minute (PGM). On the other hand, pressure is the force, or push, behind the water and is measured in pounds per square inch (psi).

Optimal water pressure — and the flow that results from it — is essential for efficient and uniform irrigation in residential and commercial systems. Variations from this optimal pressure — often due to excessive pressure in domestic water supply — will lead to inefficiencies.

“What has the most potential to increase [irrigation system] inefficiency, to decrease uniformity and to increase water waste and water bills? Without a doubt, that’s nonoptimal water pressure,” Davis says.

While numerous variables — rotor heads, spray heads, drip systems — influence a system’s optimal water pressure, irrigation experts say most systems operate within a range of 30 to 45 psi, with drip systems between 15 and 30 psi. Conversely, the average municipal water system could be upwards of 80 psi.

Excessive pressure in an irrigation system will lead to a range of consequences, Davis says. In addition to damaging a system’s components, high pressure makes pipes, fittings and sprinkler heads susceptible to bursting or cracking. This results in leaks that require costly repairs.

Malfunctioning sprinkler heads under high pressure, in particular, produce a fine mist instead of a proper spray pattern, which leads to over-watering, over-spraying and wasted water, Davis explains.

“There are a multitude of products available to manage this pressure,” he says. “We can regulate pressure at the source, and we can regulate pressure at the valve, which is even better. The best is to pressure regulate at the sprinkler itself.”

And pressure inadequacies go both ways. Low system pressure produces its own issues with uneven and insufficient water distribution. For example, Davis says sprinkler heads designed for a specific pressure range will produce weak, inconsistent spray patterns, leaving areas to receive minimal coverage. Similarly, drip irrigation systems will fail to deliver their intended flow rate, causing plants to suffer from water stress.

This low-pressure disruption in water coverage often leads to excessive system run times as a compensatory measure. “So, instead of addressing the low-pressure issues, we’re instead relying on inappropriate, nonoptimal water pressure to continue to manage lower water pressure,” Davis says.

Troubleshooting low-pressure issues is potentially more complex. “An irrigation pro may need to replace the sprinkler nozzles, or they may be forced to separate the entire system into smaller zones,” Davis advises. “Or it may even require installing pressure-boosting equipment to address the low-pressure issues. But remember, we want to provide our sprinklers with optimum pressure because optimum pressure is the best scenario for an irrigation system.”

Preventative measures

While irrigation components are generally durable, proper maintenance is essential for hydraulic longevity. The frequency of regular maintenance varies significantly based on the end user’s expectations, budget and desired landscape quality. Often, though, preventive maintenance practices are overlooked by owners or managers, Malkin says.

Regular maintenance — performed routinely during spring startups and fall shutdowns — is crucial and should focus on water distribution components like sprinkler heads and drip systems, which require periodic checks to ensure functionality.

“Regular inspections are critical to identifying issues like clogged nozzles, dirty filters and misaligned sprinklers,” Davis says. “All of these will impact uniformity and efficiency.”

Get smart

Education is an irrigation pro’s most valuable tool in troubleshooting hydraulic issues in an irrigation system. It is critical to understand proper irrigation system hydraulics, and continued training is critical to ensure efficient and correct system management, says Rick Malkin, product manager at Rain Bird Corp.

The entire industry suffers from improper system installations and modifications by individuals lacking hydraulic knowledge, leading to inefficiency and water waste, negatively impacting the entire industry’s reputation, Malkin says. Despite having excellent products and dedicated professionals, the proper application of hydraulic principles is crucial for effective and sustainable irrigation practices.

“So, go get the knowledge and learn hydraulics,” he says. “That will really help you, and it will help you with your customers. You’ll have the knowledge and engineering background to do these things correctly. There’s real science behind this, and [irrigation pros] need to pay attention to that.”

Next, Malkin recommends examining piping systems for leaks and breaks. In addition, valves, especially electric ones, require regular inspection to ascertain the wear and tear of their internal components, like diaphragms and solenoids.

On the controller side, Malkin adds that electronics and internal wiring should be inspected for possible faults that could hamper system controls and flow monitoring equipment. Likewise, he says improper controller programming and scheduling result in significant water waste, so these software components should be checked, updated and adjusted when necessary.

“This plays a significant role in system hydraulics, too, because these systems will waste a lot of water if they’re not properly programmed to turn things on and off when they should,” he says.

Irrigation technology also plays a crucial role. Malkin says that flow sensors, once expensive and limited to large-scale applications, are now much more affordable and available for smaller residential and commercial use. These sensors allow for manual and automatic water flow monitoring, enabling users to set flow limits and receive alerts for anomalies such as leaks.

“The cost barrier to use [flow-sensing] technology on smaller systems has nearly gone away,” he says. “From an installation standpoint, [flow-sensing technology] requires a couple of extra components, but the money it can save clients and [the ways it can] help to prevent future system problems makes that less of an issue.”

Ultimately, like with regulating pressure, monitoring flow is essential for preventing hydraulic problems, as it allows for early detection and mitigation of more complex and costly customer issues, Malkin says.