Installing an irrigation system that is well-designed, effective, efficient and built to last is every contractor’s ultimate goal. These simple tips from irrigation professionals will help you navigate the process, avoid common pitfalls and ensure that your irrigation system installation is able to withstand the test of time.

Do your homework

Before the trenching begins, there is plenty of work to be done to ensure that the end result checks all the boxes. A designer needs a variety of data in hand before an efficient and effective irrigation system design can take shape, says Keith Klusmeyer, a landscape and irrigation designer at Bergman Nurseries in Quincy, Illinois.

“You’re going to need the gallons per minute the system is capable of running, the static pressure of the system with nothing running and the service line and service meter size,” Klusmeyer says. “Once you have that info, it makes the overall design process easier to come up with.”

There are a few different ways to determine the water capacity on a job site, from a pressure gauge that attaches to the spigot, to the old-fashioned bucket test, to some basic number crunching.

“You can stick a bucket under the faucet and time how long it takes to fill up a 5-gallon bucket or you can go in and do the math,” Klusmeyer says. “What size is your service line coming in? What size meter do you have? That will give us an idea of our gallons per second.”

Failing to properly calculate the water capacity can have serious implications on an irrigation installation, no matter how well the system is designed. While the system might throw water, it will not operate efficiently, which is the name of the game in irrigation today.

“If my heads are supposed to throw 30 feet and I don’t have the pressure, it is going to go 24 or 25 feet,” Klusmeyer says. “If I based my design on head-to-head coverage, I’m not efficient with my system. Before we start the installation, we want to do the homework to make sure that once the system is installed, it will run efficiently.”

With the necessary calculations in hand, product data catalogs produced by most manufacturers serve as an invaluable source of information, as they are a comprehensive resource about the various products.

“Use those product catalogs to tell you everything you need to know when designing a system, from how far the head will throw to the pressure circumstance and friction losses,” Klusmeyer says. “Catalogs from suppliers are very important to us because it gives us all the data and information we need.”

Installing an irrigation system that fills the current need is good, but installing a system that can accommodate the needs of tomorrow is excellent.

Plan for expansion

Installing an irrigation system that fills the current need is good, but installing a system that can accommodate the needs of tomorrow is excellent, says Andy Slack, the owner of Slack Landscape and Irrigation Consulting in Buckeye, Arizona. He encourages irrigation professionals to think big when it comes to design and installation. Allowing for the ability to expand a system in the future requires a small investment up front, but it saves tremendous time and expense when and if a system requires expansion.

“Overdo it when it comes to design, and overdo it when it comes to installation,” says Slack. “If you need to add onto the system in the future, it won’t be able to perform very well if it doesn’t have any overage in it.”

The trick is figuring out just how big to go. Slack says with piping, he typically chooses the next size. For a job that calls for a 1-inch pipe, he would use a 1.5-inch pipe. When it comes to wires, Slack says he also ensures that there is room to expand with time.

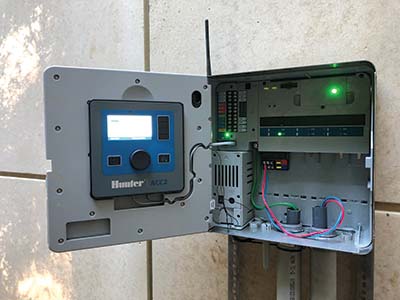

“You may need 23 zones on an irrigation controller with a 24-zone capacity, but for an extra $50 or $100 when you’re installing, you can add a few wires and upsize the controller so it will have the capabilities to expand,” he says. “You don’t want to increase too much, because you’re adding significant cost, but it doesn’t cost that much to increase the capacity of the system at design or installation compared to upsizing the capacity down the road.”

Because building a plan with the capacity for expansion might come with a heftier price tag than a competitor’s proposal, Slack says providing some client education is a key piece of the process.

“Educating the customer on the reality of what will happen down the road if they want to expand is important,” Slack says. “They can spend an extra 10% on installation and they will have plenty of capability down the road.”

Educating the customer on the reality of what will happen down the road if they want to expand is important. – Andy Slack, Slack Landscape and Irrigation Consulting

Dig in

The calculations are complete, the plans are drawn and the supplies are on-site, but there is one key step standing in the way of the trencher hitting the dirt.

“Before you start any job, you want to call for a line locate,” says John Watson, operations manager at All About Irrigation in Flowery Branch, Georgia. “Don’t do any digging before you call for a line locate to mark all your utilities.”

With the all-clear to begin digging, Watson says that patience is a virtue and a key piece in installing a system that stands the test of time. Whether trenching, plowing or hand digging, allowing enough time to do the job correctly is crucial.

“Depending on the size of the job and the size of the equipment, that will determine what kind of equipment you’ll use,” Watson says. “A job that is established already with mature landscaping, whenever possible, you’d want to dig in the beds where it will be undetectable, or you can use a vibrator plow and pull the pipe in the ground. Whatever method you choose, you want to make sure you have enough time so you don’t have to rush.”

Jobs that are pulled too quickly will be too shallow. Finding the proper speed and depth to plow often comes with experience, Watson says.

“If a system is installed too shallow, when the weather changes, that movement that goes on in the ground with the pipe can cause damage,” Watson says. “Or, when people aerate, it gets damaged from the aerator or from surface erosion. We have also seen that if there has been a power surge into the ground from lightning or lightning that struck nearby, shallow jobs with multistrand wire are more prone to lightning damage.”

While proper depth is determined by regional requirements, Watson says that a depth of 10 to 12 inches is common for residential jobs, while a couple feet deep is more common for commercial installations.

In addition to digging deep enough, Watson says that contractors should also make sure they dig big enough so they have room to work. He equates installing an irrigation system to fitting together a puzzle.

“Everything we do is fittings, and you have to dig the hole big enough so you can put your puzzle together,” he says. “You need room to work, whether it is an installation or a repair.”

Take pride in the details

Each step of the irrigation installation process comes with a specific set of best practices, and that includes the final steps of installation.

While the process of securing the fittings may seem straightforward, Watson says there is a specific technique to ensure the best long-term outcome.

“Make sure to bottom your fittings out, then clean, prime and use the proper amount of glue, quarter turn the fittings, and wipe excess glue off the fitting,” he says.

Using too much glue means that excess glue is pushed into the fitting, which lays in the bottom of the pipe. The chemical reaction between the glue and the pipe is a chemical welding process, and that reaction can soften the pipe and cause integrity issues down the line, Watson says.

A few final touches go a long way toward installing an irrigation system that will withstand harsh weather, the weight of lawn maintenance equipment and frequent usage. In addition to backfilling trenches and properly tamping them down to prevent them from caving in with heavy rain, Watson also recommends clearly marking all valves and heads.

Invest in your business

The reality of the past 18 months is that supply chain issues have created equipment shortages, which have led to price increases. Contractors who are experienced estimators will build enough profit into their bids to absorb these unforeseen costs.

“Expenses change, and you should be aware that that will happen and plan accordingly,” Slack says. “You should be able to accommodate it without having to go back to the customer.”

Slack says there are a variety of classes on bidding and estimating, from virtual four-hour seminars to three-day sessions. “That stuff does exist,” Slack says. “It is a matter of investing in yourself and your business.”

As manufacturers have invested millions of dollars into product research and development, Watson also recommends keeping up with the latest technology in the industry, which allows you to be a valuable resource to clients.

“Learn by going to things from manufacturers or be involved in an association,” Watson says. “Keep up with the training to separate yourself from other contractors.”